3D printing is becoming increasingly popular, especially in the healthcare field, both for humans and in the veterinary sector. Also known as additive manufacturing, 3D printing is being used by more vets everyday to cope with anything from implants to prosthetics to tissue replacements.

Vets are slowly turning to these 3D printing medical devices because of the cost savings and the flexibility of the device to create any desired shape. There is no virtual library with limited designs; anything put into the platform can be produced in minutes, or hours for larger products.

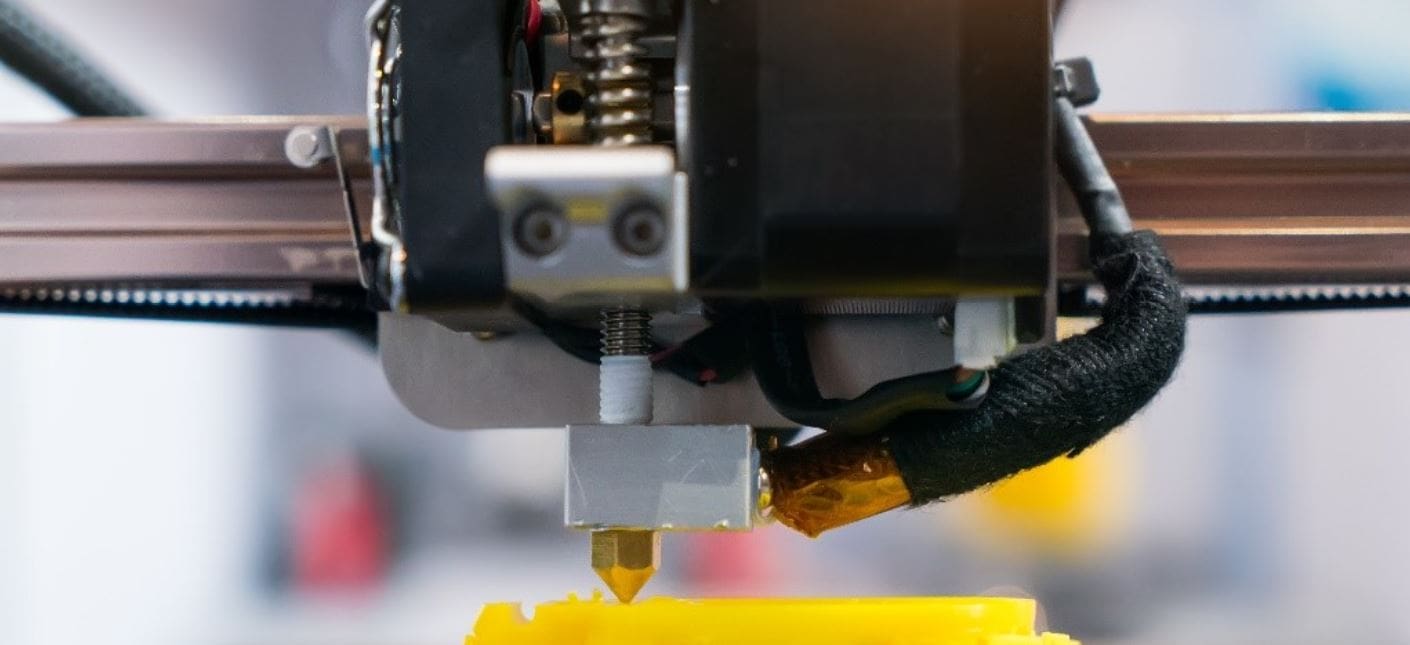

How 3D Printing Works

Each 3D printer has differing capabilities, but for veterinary medicine, the list of materials varies depending on what is being produced. But perhaps the most surprising available material is living cells.

These living cells allow the vets to print natural tissue, filled with cells and fluids. With this innovation, damaged tissue in animals could be repaired by using living cells in additive manufacturing.

Other materials used in veterinary 3D printing include:

- Plastic

- Metal

- Ceramic

- Glass

- Resin

- Nylon

- Stainless Steel

- Titanium

With additive manufacturing being relatively new to the veterinary medicine space, we’ve only began to scratch the surface of its possibilities. However, the process is already down to a science.

3D Printing Process:

- Gather 2D info from CT scans and x-rays

- Import the info into a Computer-Aided Design (CAD)

- CAD virtually designs two-dimensional models

- Models are fitted and sized to the selected dimensions

- Software sends the information to the 3D printer

The printer will then create the model in minutes or hours, depending on the complexity or size of the model. This process is basically standard throughout the entire additive manufacturing industry, but the materials vary for each system.

Each 3D printer has differing capabilities, but for veterinary medicine, the list of materials varies depending on what is being produced. But perhaps the most surprising available material is living cells.

These living cells allow the vets to print natural tissue, filled with cells and fluids. With this innovation, damaged tissue in animals could be repaired by using living cells in additive manufacturing.

Applications in Veterinary Clinics

The possibilities are endless with something as vast as 3D printing and veterinary clinics are beginning to use them in practice. They utilize additive manufacturing mainly in preparation for surgeries or to build specific animal prosthetics for their furry little patients.

3D Model of Specific Organs or Areas

Vets will typically 3D print specific internal areas of their patients when preparing for a surgery in order to practice the procedure. The model also has the same measurements as the actual animal so the vet can practice with the correct instruments and tools for making precise incisions.

This gives the vet an exact idea of the animal they will be performing surgery on, giving them an exact model replica to prepare for before performing the actual surgery on your precious little family member.

Prosthetics and Orthotics

Much like with humans, prosthetics are becoming increasingly popular in the animal world, especially with the innovations in veterinary medicine.

The first 3D prosthetic made for a dog occurred in 2014 when 3D Systems fitted Derby, a young dog from South Carolina, prosthetics because he suffered from no front paws. This was great because the process was quick, cheap, and can be adjusted at any time with the flexibility and speed of additive manufacturing.

Other limbs can also be produced with 3D printing, such as:

- Hind legs – Dog

- Legs – Parrot

- Titanium beak – Macaw

- Jaw – Sea Turtle

Masks Post-Surgery

One of the other most popular practices in additive manufacturing is printing masks for animals after a surgery. Think of these as those funny-looking cones dogs must wear post-surgery to avoid reinjuring the wound.

These masks are also made by 3D printing for the bones and joints to heal. They prevent the dog from scratching their face or any other area that needs recovering.

Benefits of 3D Printing

We’ve already discussed most of the benefits of additive manufacturing above but there’s even more than what we already went over!

Top Benefits of 3D Printing for Vet Use:

- Plan for Procedures with Models

- Customizable Tools to use During Surgeries

- Models for Bone Replacement

- Creates Prosthetics

- Orthopedic Implants

- Overall Decreases surgery time

Not only does 3D printing aid in these areas, but it provides peace-of-mind to the owners of the puppers and kitties because of the increased practice with 3D models going into procedures. The model also provides increased diagnosis for internal issues or structural damage with the bones or vertebrae.

University Programs using 3D Printing

While some might think 3D printing is exclusively in veterinary clinics, it’s actually the opposite. A lot of vet practices haven’t had the opportunity to use the innovative technology, however, universities are pioneering this new tech. Due to increased funding and donations, some veterinary medicine programs have the privilege of using additive manufacturing.

These universities are currently practicing 3D Printing for vets:

- Ohio State University

- University of Pennsylvania

- Pennsylvania State University

- North Carolina State University

- University of Tennessee

- University of Florida

- Purdue University

- Auburn University

- Cornell University

- University of Wisconsin-Madison

All the colleges of veterinary medicine at each university uses the technology in a different way. While Wisconsin-Madison uses additive manufacturing for prosthetics after an orthopedic surgery, Tennessee uses it for models to teach their students before an exam.

3D Printing is The Future

With all the advancements being made in technology on a daily basis, 3D printing is sure to expand and grow like we haven’t seen before. Colleges are even priming the next generation of vets with this new technology so they can be familiar once they reach the workplace.

The number of 3D printing medical devices is sure to increase, along with their capabilities in the veterinary medicine field. This is just the beginning for additive manufacturing.